162TX

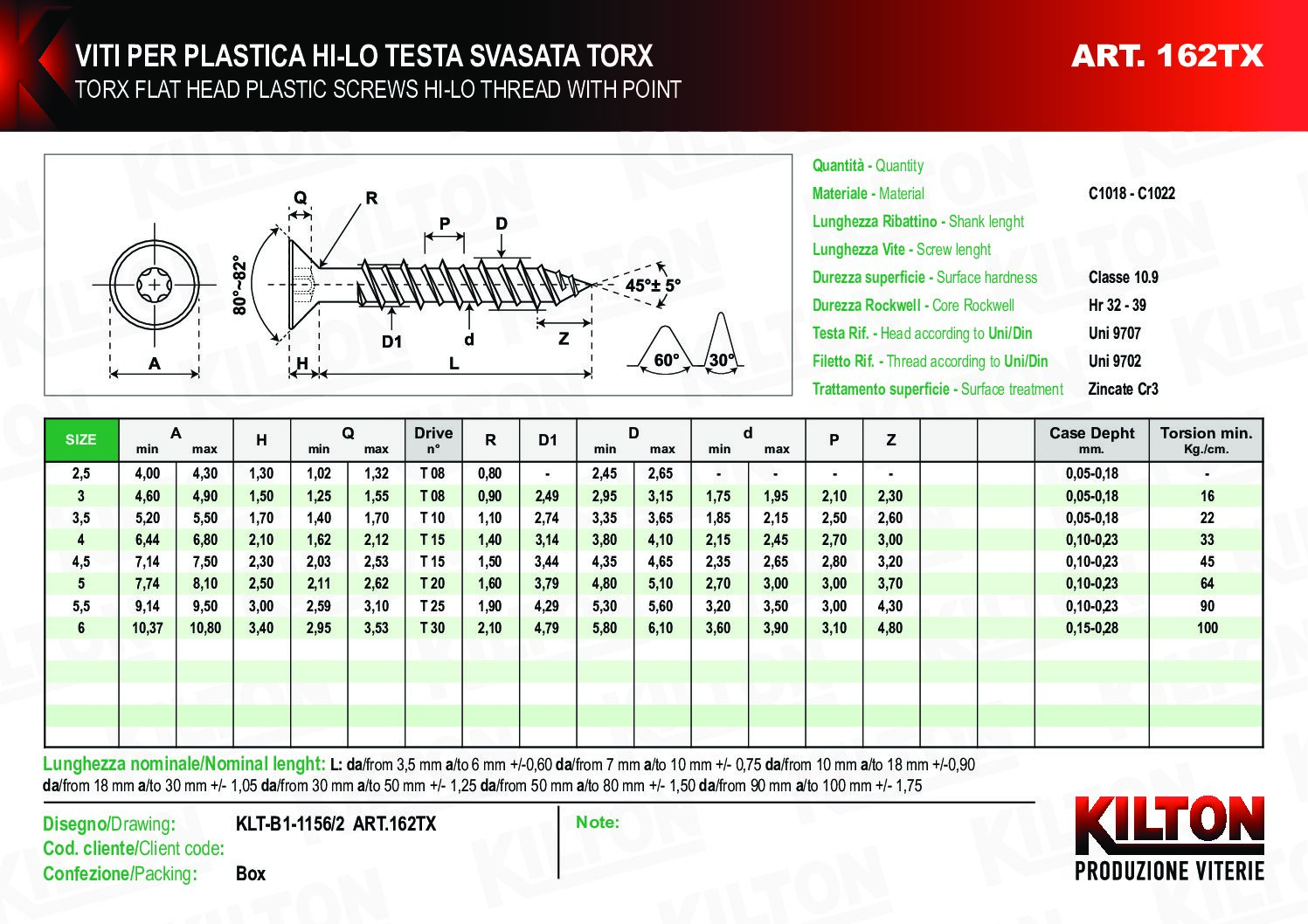

TORX FLAT HEAD PLASTIC SCREWS HI-LO THREAD

The pros and cons of Hi-Lo are these, but not only: for this reason we always recommend contacting the office for more comprehensive and targeted advice.

The use of Torx allows to transmit a higher tightening torque than other impressions. It is a universal type of impression, unlike the specific ones that are used in the various countries of the world (cross, philips, pozi, slotted, square impressions and so on). Torx is particularly suitable for diameters from 4 upwards; applying it on smaller diameters is not particularly recommended as the reduced depth of the impression with respect to a cross can create problems during assembly. Precisely for this reason, if they are not mounted perfectly in line with the holes and with the screwdriver, the insert could escape from the screw seat.

The length of the screw is calculated by measuring the screw including the head.

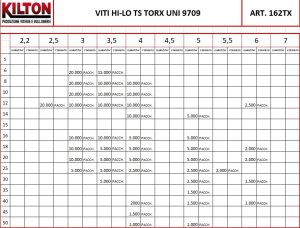

Code

Description

Availability

Certifications

Request offer

162TX.03010ZN

VITI HI-LO 3X10 TS TORX T 08 UNI 9709 ZINCATE Cr.3

0.0

162TX.03012ZN

VITI HI-LO 3X12 TS TORX T 08 UNI 9709 ZINCATE Cr.3

0.0

162TX.03014ZN

VITI HI-LO 3X14 TS TORX T 08 UNI 9709 ZINCATE Cr.3

0.0

162TX.03016ZN

VITI HI-LO 3X16 TS TORX T 08 UNI 9709 ZINCATE Cr.3

0.0

162TX.03018ZN

VITI HI-LO 3X18 TS TORX T 08 UNI 9709 ZINCATE Cr.3

0.0

162TX.03020ZN

VITI HI-LO 3X20 TS TORX T 08 UNI 9709 ZINCATE Cr.3

0.0

162TX.03025ZN

VITI HI-LO 3X25 TS TORX T 08 UNI 9709 ZINCATE Cr.3

0.0

162TX.03510ZN

VITI HI-LO 3.5X10 TS TORX T 10 UNI 9709 ZINCATE Cr.3

0.0

162TX.03512ZN

VITI HI-LO 3.5X12 TS TORX T 10 UNI 9709 ZINCATE Cr.3

0.0

162TX.03514ZN

VITI HI-LO 3.5X14 TS TORX T 10 UNI 9709 ZINCATE Cr.3

0.0

162TX.03516ZN

VITI HI-LO 3.5X16 TS TORX T 10 UNI 9709 ZINCATE Cr.3

0.0

162TX.03518ZN

VITI HI-LO 3.5X18 TS TORX T 10 UNI 9709 ZINCATE Cr.3

0.0

162TX.03520ZN

VITI HI-LO 3.5X20 TS TORX T 10 UNI 9709 ZINCATE Cr.3

0.0

162TX.03525ZN

VITI HI-LO 3.5X25 TS TORX T 10 UNI 9709 ZINCATE Cr.3

0.0

162TX.03530ZN

VITI HI-LO 3.5X30 TS TORX T 10 UNI 9709 ZINCATE Cr.3

0.0

162TX.04010ZN

VITI HI-LO 4X10 TS TORX T 15 UNI 9709 ZINCATE Cr.3

0.0

162TX.04012ZN

VITI HI-LO 4X12 TS TORX T 15 UNI 9709 ZINCATE Cr.3

0.0

162TX.04014ZN

VITI HI-LO 4X14 TS TORX T 15 UNI 9709 ZINCATE Cr.3

0.0

162TX.04016ZN

VITI HI-LO 4X16 TS TORX T 15 UNI 9709 ZINCATE Cr.3

0.0

162TX.04018ZN

VITI HI-LO 4X18 TS TORX T 15 UNI 9709 ZINCATE Cr.3

0.0

162TX.04020ZN

VITI HI-LO 4X20 TS TORX T 15 UNI 9709 ZINCATE Cr.3

0.0

162TX.04025ZN

VITI HI-LO 4X25 TS TORX T 15 UNI 9709 ZINCATE Cr.3

0.0

162TX.04030ZN

VITI HI-LO 4X30 TS TORX T 15 UNI 9709 ZINCATE Cr.3

0.0

162TX.04035ZN

VITI HI-LO 4X35 TS TORX T 15 UNI 9709 ZINCATE Cr.3

0.0

162TX.05016ZN

VITI HI-LO 5X16 TS TORX T 20 UNI 9709 ZINCATE Cr.3

0.0

162TX.05018ZN

VITI HI-LO 5X18 TS TORX T 20 UNI 9709 ZINCATE Cr.3

0.0

162TX.05020ZN

VITI HI-LO 5X20 TS TORX T 20 UNI 9709 ZINCATE Cr.3

0.0

162TX.05025ZN

VITI HI-LO 5X25 TS TORX T 20 UNI 9709 ZINCATE Cr.3

0.0

162TX.05030ZN

VITI HI-LO 5X30 TS TORX T 20 UNI 9709 ZINCATE Cr.3

0.0

162TX.05035ZN

VITI HI-LO 5X35 TS TORX T 20 UNI 9709 ZINCATE Cr.3

0.0

162TX.05040ZN

VITI HI-LO 5X40 TS TORX T 20 UNI 9709 ZINCATE Cr.3

0.0

162TX.06018ZN

VITI HI-LO 6X18 TS TORX T 30 UNI 9709 ZINCATE Cr.3

0.0

162TX.06020ZN

VITI HI-LO 6X20 TS TORX T 30 UNI 9709 ZINCATE Cr.3

0.0

162TX.06025ZN

VITI HI-LO 6X25 TS TORX T 30 UNI 9709 ZINCATE Cr.3

0.0

162TX.06030ZN

VITI HI-LO 6X30 TS TORX T 30 UNI 9709 ZINCATE Cr.3

0.0

162TX.06035ZN

VITI HI-LO 6X35 TS TORX T 30 UNI 9709 ZINCATE Cr.3

0.0

162TX.06040ZN

VITI HI-LO 6X40 TS TORX T 30 UNI 9709 ZINCATE Cr.3

0.0

UNI 9709/TA

The Hi-Lo screw is easily distinguishable from any other screw due to the characteristic alternation of the thread between high (high) and low (low). It was one of the first screws designed specifically for plastics, especially for very soft materials such as nylon, moplen and the like. The highest thread at 30 ° is the one in charge of ensuring the tightness of the screw in the plastic material, while the smaller one should serve to create a blocking action of the screw by virtue of the different angle at 60 °. In practice, the product behaves like the double-principle rapid-fix "cousin" used in the wood sector: the idea for a screw with similar sealing characteristics, but on plastic materials, developed from the latter. Just like its like, the critical points of this article are varied and should be considered more often in the design phase, so that this screw can be used on a broader spectrum in a much more conscious way as it happens for Plastic-Fix (art. 105 and derivatives). Analyzing the difficulties of the screw, for example, in our experience we have had to deal with plastic products whose pre-hole being too large (this due to the needs of molding and blowing of the plastic) did not allow the lower thread of the screw to comply with the locking action and / or in any case not to have any grip on the material. In fact, by working only one thread, the tightness of the screw is not as it was originally thought. A second case concerns the size of the head which, with the same nominal diameter of the stem, is far less than any other type of product for plastics: the most striking example is found in the 3.5mm diameter screw whose head has a diameter of 5.6mm and with cross 1 instead of 7mm and with cross 2 as in all the others. An apparent strength of the product could be seen in the double step that allows a faster screwing than a normal screw for plastic: unfortunately this value becomes negative when looking at the tightness of the product with the same tightening torque.