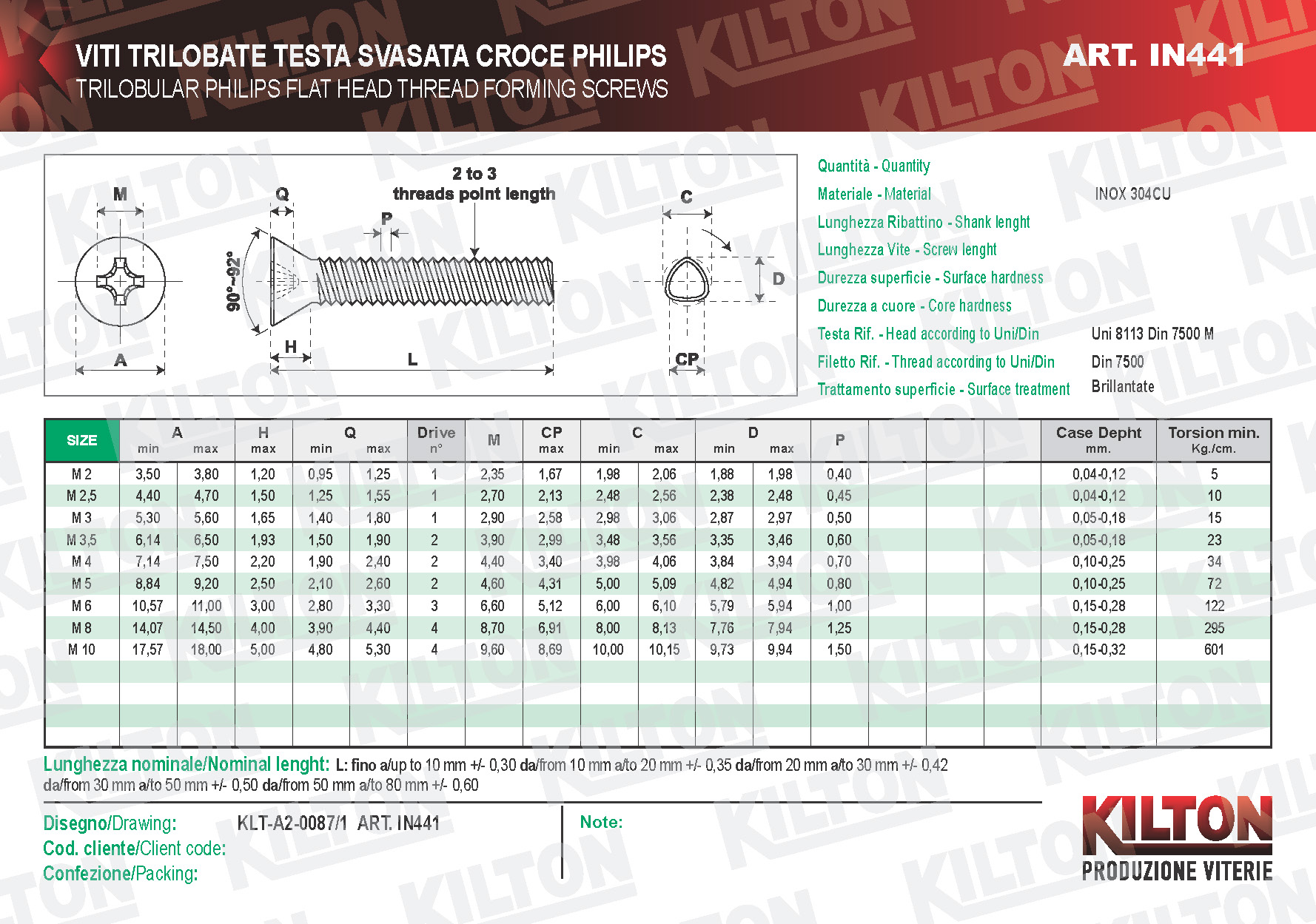

IN441

PHILIPS FLAT HEAD THREAD FORMING SCREWS INOX A2

The length of the screw is calculated by measuring the screw including the head.

Code

Description

Availability

Certifications

Request offer

IN441.0306

VITI INOX A2 TRILOBATE M3X6 TS+

0.0

IN441.0410

VITI INOX A2 TRILOBATE 4X10 TS+

0.0

IN441.0414

VITI INOX A2 TRILOBATE 4X14 TS+ UNI 8113

110350.0

IN441.0516

VITI INOX A2 TRILOBATE 5X16 TS+ UNI 8113

0.0

IN441.0630

VITI INOX A2 TRILOBATE 6X30 TS+ UNI 8113

31690.0

IN441.0635

VITI INOX A2 TRILOBATE 6X35 TS+ UNI 8113

19430.0

IN441.4012

VITI INOX A2 TRILOBATE 4X12 TS+

0.0

UNI 8113 - DIN 7500M

The self-tapping tri-part screw is a triangular cross-section screw with a metric thread suitable for direct screwdriving into blind or through holes. Its main characteristic is to avoid the threading phase in steel and light alloy products. This screw during the screwing phase forms the thread plastically, i.e. by deformation of the material, thus creating a backlash-free coupling between the screw and the lead screw, thus ensuring optimal fastening with high resistance to tearing and unscrewing due to vibrations of use. The creation of the thread in this condition avoids the formation of chips, a feature particularly required by several standards relating to threads on blind holes. Regardless of the length of the screw, the efficiency of this thread is expressed only in the first 20/25mm starting from the tip. Any presence of a longer thread length has no effect on the holding capacity of the screw. The utmost attention must be paid to the holes or die-casting pins that will be used to create the holes: an incorrect hole even as little as five hundredths can in some cases radically change the tightness of the screw. It should also be said that not all the tables in circulation are correct for the use of the screws in question; This situation was created as a result of the regulatory grouping of various types of self-forming screws which, however, had different characteristics and therefore different holes for use. From our long and established technical experience we can say that the hole suitable for any type of use is four or five tenths maximum lower than the nominal diameter of the screw; in the case of die castings, a maximum taper of one degree must be calculated. Different tapers can create problems during particularly heavy tightening, as they interfere with the standard of the screw: it can in fact have a forming part of four times its pitch. Our three-lobed screws, in addition to the galvanic treatment according to RoHs regulations, are subjected to a lubrication treatment, necessary to reduce the screwing effort by 30%.