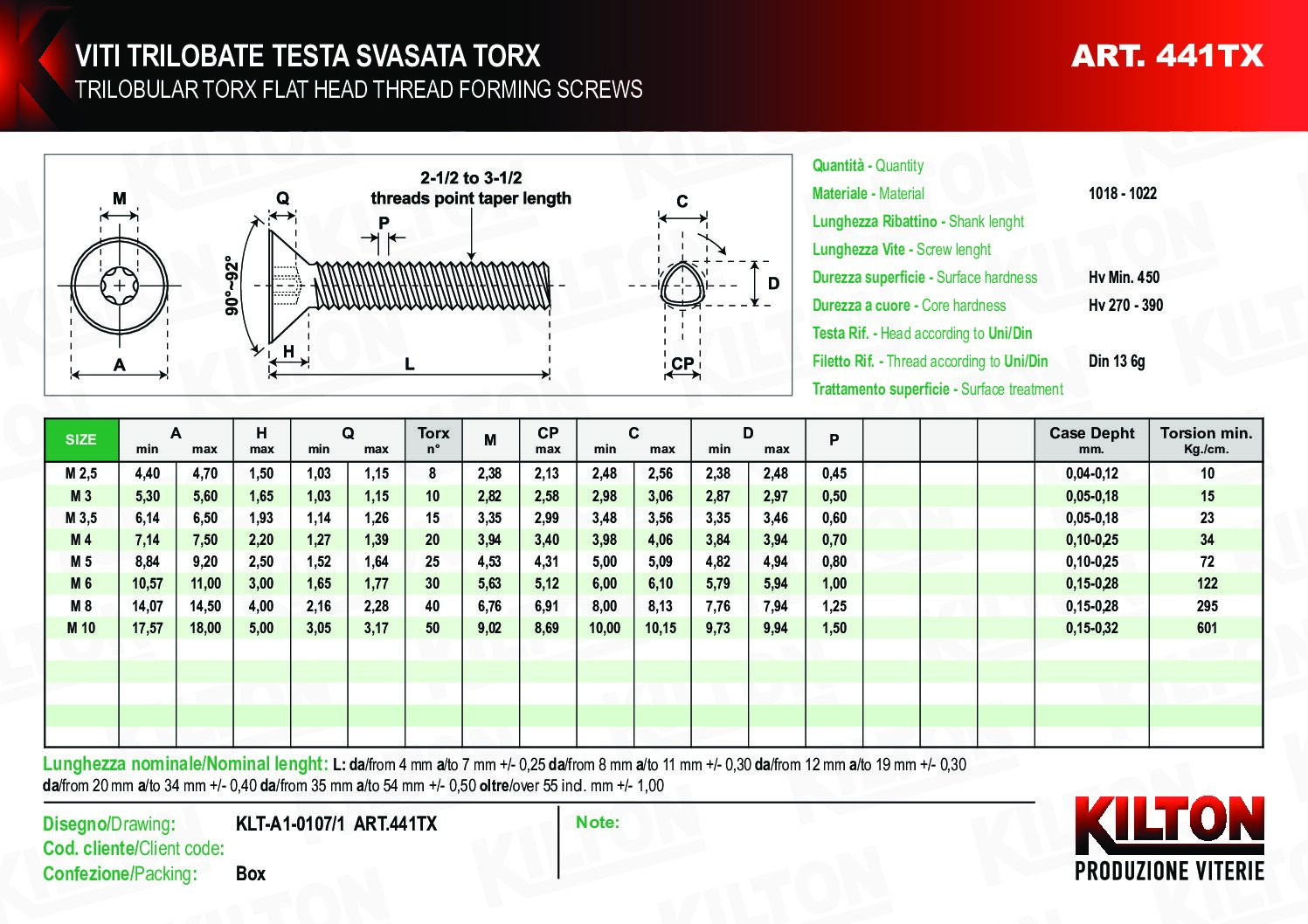

441TX

The self-forming trilobe screw is a triangular section screw with metric thread suitable for direct screwing in blind or through holes. Its main feature consists in avoiding the threading phase in steel and light alloy products. During screwing, this screw forms the thread plastically, i.e. by deformation of the material, thus creating a play-free coupling between screw and nut, thus ensuring optimal fastening with high resistance to tearing and unscrewing due to the vibrations of use. The creation of the thread in this condition avoids the formation of shavings, a feature particularly required by several regulations concerning threads on blind holes. Regardless of the screw length, the efficiency of this thread is expressed in the first 20 / 25mm only starting from the tip. The presence of a longer thread length does not affect the screw's sealing capacity. The utmost attention must be paid to the holes or die-casting pins that will be used for the creation of the holes: an incorrect hole even if only five cents can in some cases radically change the tightness of the screw. It should also be said that not all the tables in circulation are correct for the use of the screws in question; this situation was created following the regulatory grouping of various types of self-forming screws, which however had different characteristics and therefore different holes for use. From our long and affirmed technical experience we can maintain that the hole suitable for any type of use is four or five tenths maximum smaller than the nominal diameter of the screw; in case of die-casting, a maximum taper of one degree must be calculated. Different tapers can create problems during particularly heavy tightening, as they interfere with the regulation of the screw: it can in fact have a forming part of four times its own pitch. Our trefoil screws, in addition to the galvanic treatment according to RoHs regulation, are subjected to a lubrication treatment, necessary to reduce the screwing effort by 30%.

The use of Torx allows to transmit a higher tightening torque than other impressions. It is a universal type of impression, unlike the specific ones that are used in the various countries of the world (cross, philips, pozi, slotted, square impressions and so on). Torx is particularly suitable for diameters from 4 upwards; applying it on smaller diameters is not particularly recommended as the reduced depth of the impression with respect to a cross can create problems during assembly. Precisely for this reason, if they are not mounted perfectly in line with the holes and with the screwdriver, the insert could escape from the screw seat.

The length of the screw is calculated by measuring the screw including the head.

TORX FLAT HEAD THREAD FORMING SCREWS